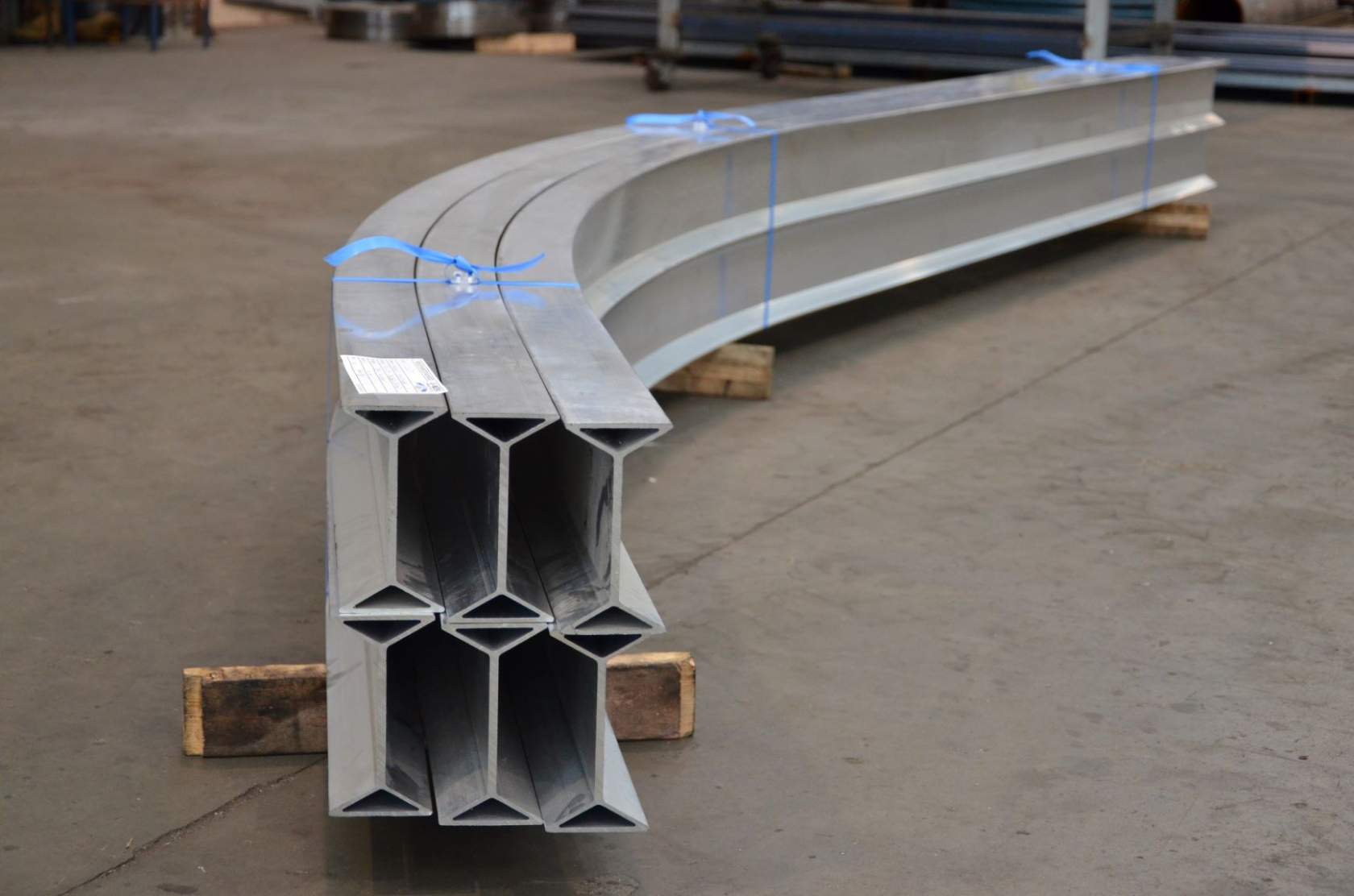

Rolling

Using CNC section rolling machines, we roll all steel and stainless-steel sections, pipe and tubes to the radius required.

We also can aluminium extrusions, many of which have complex shapes.

Click here to view section rolling leaflet. This document is also helpful if you are unsure of the meaning of many of the terms used on this page as it includes diagrams of many different sections and orientations

Click here to view a table of minimum diameters that can be rolled for most sections.

Rolled coils

Helical Coils / Cylindrical Coils

Helical coils are frequently used for heating or cooling product in processing plant tanks and vessels. Tube coils provide an economical and straightforward method of obtaining heat transfer surface area. Tube coils are made by rolling lengths of tubing into helixes or double helixes in which the inlet and outlet are located side by side. We can supply coils in various metals. including titanium coils and duplex stainless coils, all of which can be supplied in segments or fully fabricated and hydrostatically tested.

Helical coils have a variety of different parameters:

Pitched or Close wound:

Pitched coils are wound at constant centre-to-centre pitch that is larger than the tube/pipe diameter. Larger or heavier pitched coils are normally provided with 3 or 4 supports. These supports are U-bolted to the tube. Close wound coils have a pitch equal to the tube/pipe diameter and are normally stitch welded together for rigidity.

Direction of Winding:

Direction is not normally important, but coils can be wound in either direction. the direction of winding is defined as clockwise or anti-clockwise up, when viewed from the top.

Single Start Coil / Multi Start Coil:

Most heating/cooling coils are single start but they can also be 2, 3, 4 or 5 start.

Coil sets:

Coils can be single helical, or they can be made in sets. With a double set, there is an inner coil and an outer coil. Normally, the inner coil is wound in the opposite direction to the outer coil so that the 2 coils can be connected at one end by a simple “crossover”.

Ends:

There are many types of arrangements, but the most common are:

90°ends

Ends are at top and bottom

2 x 90° ends at one end, with an internal riser

Tangential ends

Flat Spiral Coils (Pancake)

Pancake coils are often used in heating applications where heat must only be applied at the lowest point of the vessel and thus a cylindrical coil is not optimal. Uneek Bending can produce these coils in a wide variety of sizes.

Suction Heater U-Tube Bundles

Uneek Bending can manufacture U-tube bundles to suit your needs.

Limpet Coils (Half Pipe Coils)

Limpet coils are half round heating/cooling tubes often welded to the walls of high-pressure vessels. Uneek Bending manufactures large numbers of these coils for a variety of different industries.