Power & Renewable Energy

We specialise in components for power stations and sugar mills.

Boiler tube bending for burner openings

Superheater elements

Economisers

Convection tubes/bending

Downcomers

Soot blower Components

Boiler tube erosion shields

Heating and cooling coils

Any curved tubing (for pressure piping application)

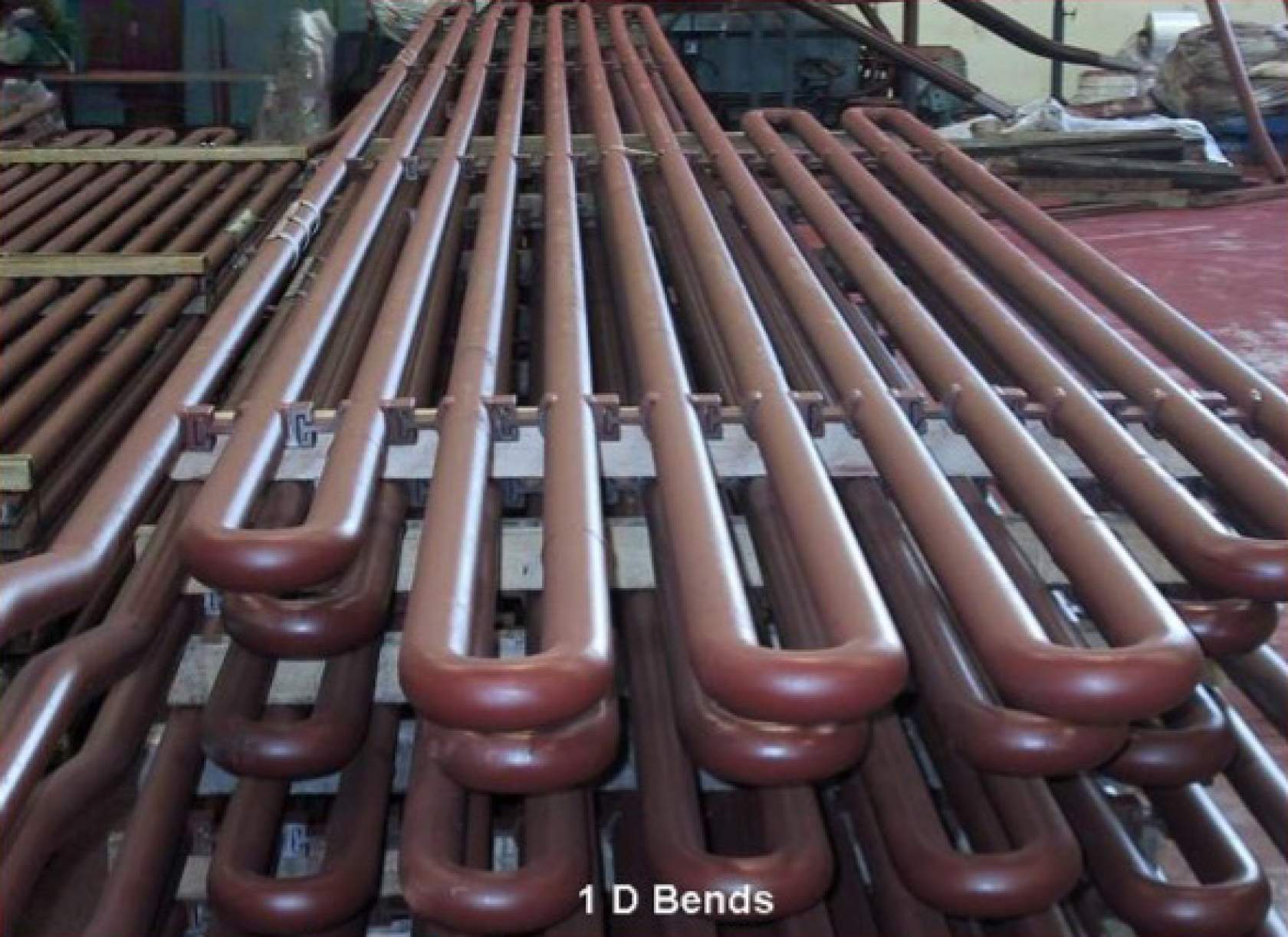

1D (or tight radius) bends

We offer a full range of NDT testing including:

Pressure testing

Radiography

Magnetic particle testing

Liquid dye penetration testing

Boiler erosion shields

Ash content, high furnace temperature, increased sootblower pressure and longer time between cleans – all these result in the likelihood of greater erosion to boiler tubes.

In such cases, the most effective course of action is to shield the erosion prone tubes with boiler erosion shields. This alternative is far cheaper than actual replacement of damaged sections of boiler tube, to say nothing of the associated downtime and loss of generation capacity and revenue that occurs with a tube leak.

Uneek Bending Co. Pty Ltd offer various types of boiler erosion shields for boiler tube protection. Typical shields cover a 180 degree segment of the tube and are 1000mm long. In addition to straight tube shields, which go over straight sections of boiler tube, we also make shields to cover bends and special shields for finned tubes. These include shields for:

Outside of bend

Inside of bend

Side of bend

Finned tube shields

We also manufacture clips that may be welded onto the shields to hold the shields in place. The shields can be manufactured to suit any tube size. The most common tube sizes are 38.1, 44.5, 50.8, and 63.5mm diameters.

The most popular erosion shield materials and sizes are 3mm and 2mm stainless steel grade UNS S30815 (Sandvik grade 253MA).